News

- the European plugFirst, the European plug 1, the European plug: also known as the French standard plug is also called the plug plug has supplier and supplier specifications such as: KE-006YX-002 and other countries and certification: (D (Denmark); N (Norway) S (Sweden); VDE (Germany); FI (Finland); IMQ (Italy); KEMA (Netherlands); CEBEC (Belgium). Product suffix: N/1225 2. The power line identification indicates the code: H05VV□□F3G0.75mm2: H: indicates European regulations, EU logo 05: indicates the power line strength (03300V05500V) VV: the front V surface core insulation layer, and the rear V represents the sheath insulation layer of the power cable. VV, for example, is denoted by RR to indicate a rubber insulation layer, such as VV: N is represented by neoprene rubber; □ □: The front [□" is specially coded, followed by [□" to indicate a flat line. If H2 is added, it means a flat two-core line; F: indicates that the line is soft line 3: indicates the number of internal lines G: represents ground 0.75mA: indicates the cross-sectional area of the power line 3, PVC: material refers to the material of the reinforcing insulating layer is below 80°C, the soft PVC also With a hardness of 78°55°, the larger the number, the harder the temperature is, and the higher the temperature of the rubber thread is, the lower the temperature of the rubber cord is 200°C. The same applies to the soft body hardness (PVC) soft body thread. Second, the British plug 1, British plug: 240V50HZ pressure 3750V3S0.5mA, fuse (3A5A10A13A) (FVSE) → fuse, size requirements: total length of 25-26.2mm middle diameter of 4.7-6.3mm both ends of the metal cap diameter of 6.25-6.5 Mm (silk screen BS1362); 2, the plug of the internal line (disassemble the BS plug is right to his right for the L line (fire) fuse, the length of the ground wire must be greater than (FireWire, zero line) 3 times the length of the fixed screw to loosen with external force to pull out The line must be finally dropped (fixed screws fixing the three lines must be tapered). 3, the power cord identification with the European plug. Third, the United States plug 1, the United States plug: 120V50/60HZ is divided into two core wire, three core wire and polarity, non-polarity, to the United States power plug copper sheet must have rubber sleeve; The two-core printing line indicates the FireWire; the polarity plug has a large zero line, and the small-footed FireWire (the power line has an uneven surface and the line surface is a FireWire); 2. There are two modes for wire rods: NISPT-2 double-layer insulation, XTV and SPT single-layer insulation NISPT-2: NISPT means double insulation, -2 surface two-core wire core insulation outer layer insulation; XTV and SPT: single-layer insulation layer, -2 surface two-core wire (thread body with groove, outer layer insulation directly copper conductor); SPT-3: single-layer insulation tape ground, -3 three-core wire (thread body with groove, the middle of the ground for double insulation); Both SPT and NISPT are off-line, and SVT is double insulated on round wire. Core Insulation Outer Layer Insulation 3, American Plugs General Use The certification number does not have a UL on the plug. Such as: E233157E236618 4, American plugs and European plugs are different: European plug use "H" said; How many lines of the U.S. regulation are used, such as: 2 x 1.31mm2 (16AWG), 2 x 0.824mm2 (18AWG): VW-1 (or HPN) 60°C (or 105°C) 300V 2: indicates the number of cores; 1.31 or 0.824mm2: indicates the core cross-sectional area; 16AWG: The cross-sectional area of the core mold, corresponding to mm2; VW-1 or HPN: VW-1 is PVC material; HPN: is neoprene rubber material 60 °C or 150 °C as the temperature of the power cord; 300V: The strength of the power cord is different from that of the European standard (European standard is indicated by 03 or 05). Fourth, Japan plug: PSE, JET VFF2*0.75mm2-F- 1. VFF: V means wire material PVC; FF is single-layer insulation layer with groove body; 2, VCTFK: VC surface material PVC; TFK for the double insulation layer deviation, outer insulation layer, inner insulation layer, copper conductor; 3, VCTF: VC said line material PVC; TF double insulation round wire; 4, the power cord is two kinds: one is 3×0.75mm2, the other is 2×0.75mm2 3×0.75mm2:3 represents a three-core wire; 0.75mm2 represents a core cross-sectional area; 5, F: indicates the software line material; 6, Japan plug three-wire plug only two pieces of inserts, the ground directly locked in the socket (safe and convenient). Fifth, the appliance's rated current corresponds to the use of software cable cross-sectional area: 1. Appliances with a crossover area greater than 0.2 and less than or equal to 3A: 0.5 and 0.75 mm2 2 Appliances greater than 3A less than or equal to 6A Application of cord cross-sectional area: 0.75 and 1.0 mm2 3, appliances greater than 6A less than or equal to 10A application of soft wire cross-sectional area: 1.0 and 1.5mm2 4 Appliances greater than 10A and less than or equal to 16A Application of soft wire cross-sectional area: 1.5 and 2.5mm2 5, appliance greater than 16A less than or equal to 25A appliance application cord cross-sectional area: 2.5 and 4.0mm2 6 Appliances greater than 25A and less than or equal to 32A Application of cross-sectional area of the cord: 4.0 and 6.0 mm2 7 Appliances greater than 32A less than or equal to 40A Application of cross-sectional area of the cord: 6.0 and 10.0 mm2 8. Apparatus application cross-sectional area greater than 40A and less than or equal to 63A: 10.0 and 16.0 mm2 Six, for the quality of more than the number of KG appliances using more power cord models: 1, 3kg the following electrical appliances (appliances) apply H03 power cord; 2, 3kg-6kg of electrical appliances (appliances) apply H05 power cord. Note: The soft (F) body power cord must not be in contact with sharp or sharp appliances. The power supply flexible (F) wire cannot withstand the contact or joint pressure by (lead, tin) welding reinforcement "easy to drop" Must pass 40-60N relay cannot fall off. 7. Power cord temperature rise test and mechanical strength test 1. Polyvinyl chloride (PVC) material line and rubber line: Assembled on electrical products, the open test power cord bifurcation shall not exceed 50K (75°C); 2, power line swing test: (fixed plug swing power line) The first kind: for the wires that will bend during normal operation, add 2kg load to the power cord 90° vertically (45° for each of the two wires) Swing 20,000 times The power cord body and plug must not have an abnormality must be turned on (frequency 1 minute 60 times); The second type: the bent wire during the maintenance of the user (the wire that will not bend during normal operation) adds 2kg load to the power cord 180° test 200 times without abnormality (frequency 1 minute 6 times). Eight, power line <br> <br> cross-sectional radius (R2) × (pi) × (number of cores) as: 0.75mm2 power line is 0.12 × 3.14 × 24 0.7536mm2

2020 08/28

- Power cables are the backbone of the power system for the transmission and distribution of large functional power.Power cables are the backbone of the power system for the transmission and distribution of large functional power. The rated voltage is generally 0.6/1KV and above. The control cable transmits the power directly to the power supply of various electrical appliances and its rated voltage is 450/750V. This makes the power cable insulation and sheath thickness thicker than the control cable during production. The difference is summarized as follows: 1. The difference between the implementation standards for power cables and control cables: The standard for control cables is 9330, and the standard for power cables is GB12706. 2. The difference between the color of the power cable and the control cable cable core: The color of the insulated cable core of the control cable is generally black and white, and the low voltage of the power cable is generally a color separation. 3. The difference between the power cable and the control cable: The control cable transfers the power from the power distribution point of the power system directly to the power connection lines of various electrical equipment and appliances. The power cable is mainly used for distribution, distribution, transmission, and change. In the power supply line, strong electric energy is transmitted, and a large current is passed. The power cable is used to transmit and distribute the large-functional power in the power system main line. 4. The difference between the power cable and the control cable cross-section: The power cable is a load wire, the current capacity increases with the increase of power, and the cross-section of the wire must increase with the increase of the current. Therefore, the specifications of the power cable are general. Larger, up to 500 square meters (range that conventional manufacturers can produce). Relatively few manufacturers can do as large cross-sections. The control cable is a secondary command wire, which controls the current-carrying operation of the contactor and other devices. The load current is very small and the cross section of the conductor is very small. Therefore, the cross-section of the control cable is generally small, and the maximum is generally not more than 10 square. 5. The difference between the number of cores of power cables and control cables: The power cable has a small number of cores, including single core, two cores, three cores, four cores (three-phase four-wire system), and five cores (three-phase five-wire system). Depending on the grid requirements, the maximum is generally 5 cores. The control cable transmits control signals with more cores, from 2 cores to 61 cores, or even more. Control cables also use various wire core structures, shielding and other measures to obtain satisfactory electromagnetic compatibility effects. 6. The difference between the rated voltage of the power cable and the control cable: The rated voltage of the power cable is generally 0.6/1kV and above, and the control cable is mainly 450/750V. 7. The difference between the power cable and the control cable: The power cable requires that the cable has sufficient compressive strength, tensile strength, temperature resistance, and corrosion resistance. Control cable requirements are relatively low. In the production of industrial electrical power cables and control cables of the same specifications, the insulation and sheath thickness of power cables is thicker than that of control cables.

2020 08/19

- Mica is the most widely distributed rock-forming mineraMica is a rock-forming mineral that usually assumes a pseudo-hexagonal or diamond-shaped plate, sheet, and columnar crystal form. The color varies with the chemical composition, and becomes deeper with increasing Fe content. The characteristics of mica are insulation, high temperature resistance, luster, stable physical and chemical properties, and good thermal insulation, flexibility and toughness. Most used in industry is muscovite, followed by phlogopite. Its widely used in the building materials industry, fire protection industry, fire extinguishing agents, welding electrodes, plastics, electrical insulation, paper, asphalt paper, rubber, pearlescent pigments and other chemical industries. Mica also appears as a character name in anime. Mica (mica) is the most widely distributed rock-forming mineral, and is a general name for aluminosilicates with layered structures such as potassium, aluminum, magnesium, iron, and lithium. Mica is prevalent in many types, among which the monoclinic system is common, followed by the trigonal system, and the others are rare. The most common minerals in the mica group are biotite, muscovite, phlogopite, lepidolite, sericite and so on. Mica usually assumes a pseudo-hexagonal or rhomboid plate, platelet, and columnar crystal form. The color varies with the chemical composition and it mainly becomes deeper as the iron content increases. Muscovite is colorless and transparent or light-colored; biotite is black to dark brown, dark green and other colors; phlogopite is yellow, brown, green or colorless; lepidolite is lavender, rose red to gray. Glossy glass, pearlescent on the cleavage surface. Mohs hardness is generally 2 ~ 3.5, the proportion of 2.7 ~ 3.5. The cleavage of the parallel bottom surface is extremely complete. Muscovite is one of the widely-distributed rock-forming minerals and has yields in all three major rock types. Mudstones can form sericite during metamorphism in low-grade areas and become muscovite when the metamorphism is slightly high. During the late stage of acid magma crystallization and pegmatism, a large amount of muscovite was generated. It can also be generated during the process of alteration from high temperature to low temperature. The so-called geology is one of the high-temperature alterations that can form a large amount of muscovite. The so-called sericitization is one of the moderate-low-temperature alterations that can form a large amount of sericite. The muscovite is weathered and broken into very fine scales, which can either become detritus in the sediment or can be one of the mineral components of the mudstone. Muscovite and phlogopite have good electrical insulation and non-thermal conductivity, acid resistance, alkali resistance and pressure resistance, and are widely used to make electrons and electricity. Mica gas industrial insulation materials. Mica chips and powders are used as fillers. Lithium mica is also the main mineral raw material for extracting lithium. Mica minerals have long been used by humans because of their large crystals and colorful colors. In Chinese ancient books, there are records of their titles: Huapilian, Tianbing, Tianpi, Dijin, Old Scraping Gold, Qianzhi Paper, Yuanyang, Yunmiqi and Xionghei. The pigment used in Tang Cave 112 of the Mogao Grottoes in Dunhuang was shiny and bright. After X-ray diffraction analysis, the natural muscovite was finely ground. Excellent color rendering. Although China has long recognized and used muscovite and phlogopite, the formal exploration of the mica deposit was carried out after the founding of the People's Republic of China. Since 1952, the muscovite deposits in Danba, Sichuan and Tuguiwula, Inner Mongolia have been successively carried out. Census exploration and achieved better results. In 1958, the National Mica Conference was held in Fanyi, Shanxi Province, and it was decided to vigorously carry out the census and exploration of mica. At that time, the discovery of the Altai Mica deposit in Xinjiang played a major role in the development of mica resources in China, and also provided a survey for the mica deposit. Exploration work has accumulated experience. Subsequently, the discovery of the MgSi muscovite deposit in the East China Sea in Jiangsu Province was utilized by industry and new industrial mica species were added to China. Mica deposits in Wulashan, Dabieshan, Qinling, Liaoning, Sichuan, and Yunnan in Inner Mongolia have been discovered one after another and expanded mica resources. Since the 1980s, the departments of building materials, mines and mines have launched General survey of mica on crushing mica and sericite. To date, the Lubaishan Village in Lingshou, Hebei Province, is China's largest producer and processor of crushing mica and biotite. After detailed investigation, he discovered the crushing mica mine at the gate of Tanzhuang Township, Lingshou, Hebei Province, discovered sericite sites in Inner Mongolia, Liaoning, and Hubei, and made progress in the industrial application research of crushing mica and sericite. In the 1950s and the mid-1970s, China had listed muscovite and phlogopite as strategic resources. The earliest mining was the Sichuan Danba mica mine, and later Xinjiang, Inner Mongolia, Shanxi, Hebei, Shandong, Henan, Shaanxi, and Yunnan. Mica mines in the provinces and autonomous regions have been mined in succession. The main state-owned mines are Altay in Xinjiang, Danba in Sichuan, and Tuguiwula in Inner Mongolia. There are also hundreds of county offices, townships, and individual mines. Before 1978, the annual production of industrial raw material mica was 1,700-2,500 tons. After 1978, the output decreased year by year due to fundamental changes in the mica consumption structure. Mineral characteristics Mineral composition of ore The main minerals of muscovite pegmatite ore are micro-plagioclase, feldspar, quartz, and muscovite. The secondary minerals are biotite, garnet, and electricity. Mica, apatite, beryl, and ilmenite. Apatite, tremolite, diopside, calcite, carbonate rock and microcline are often found in the veins of the phlogopite deposits. Muscovite in the fine fine muscovite deposit generally accounts for 50-70%, potassium feldspar and quartz accounts for about 10%, trace minerals are magnetite and limonite. Mineral characteristics of the target mineral Mica is an aluminosilicate mineral with a continuous layered silica tetrahedral structure. Divided into three sub-categories: muscovite, biotite and lepidolite. Muscovite includes muscovite and its subspecies (sericite) and less common sodium mica; biotite includes phlogopite, biotite, ferrobite, and manganese biotite; lepidolite is a variety of mica rich in lithium oxide. Small scales. Industrial use, especially in the electrical industry, is muscovite and phlogopite. Muscovite has the chemical formula KAl2[AlSi3O10][OH]2, wherein SiO2 is 45.2%, Al2O3 is 38.5%, K2O is 11.8%, and H2O is 4.5%. In addition, it contains a small amount of Na, Ca, Mg, Ti, Cr, Mn, Fe and F. Wait. The chemical formula of phlogopite is KMg3[AlSi3O10][F,OH]2, among which K2O is 7 to 10.3%, MgO is 21.4 to 29.4%, Al2O3 is 10.8 to 17%, SiO2 is 38.7 to 45%, and H2O is 0.3 to 4.5% , with a small amount of Fe, Ti, Mn, Na and F and so on. a, crystal, crystal Mica is mostly monoclinic, in the form of laminated or booklet-like crystals. The well-developed mica or hexagon with six crystal faces sometimes forms pseudo-hexagonal prismatic crystals. b. Cleavage, image or pressure Mica has perfect cleavage and can be split. In theory, muscovite can be stripped to about 10, and phlogopite can be stripped into 5 or 10 slices. The hidden cleaving of mica crystals is image and compression. c, color, gloss and transparency Muscovite flakes are generally colorless and transparent, but they are often stained with shades of green, brown, yellow, and pink; the sheen of glass is a pearl sheen on the cleavage surface. Phlogopite is usually yellow, brown, dark brown or black; glass sheen, and the cleavage surface is pearl or semi-metallic luster. Muscovites have a transparency of 71.7 to 87.5% and phlogopite of 0 to 25.2%. d, hardness and elasticity The Muscovite hardness of muscovite is 2 to 2.5, the phlogopite is 2.78 to 2.85, the elastic coefficient of Muscovite is (1475.9 to 2092.7×106 Pa (15050 to 21340 kg/cm2), and the phlogopite is (1394.5 to 1874.05)×106 Pa (14220). ~19110kg/cm2).

2020 08/12

- Chinese mica heating element supplier with 50 years of experienceMain Features 1.Excellent resistance to heat and even to open flame up to 1000 Centigrade. 2.Excellent electrical insulation. 3.Flexible to be reeled. 4.Eco-friendly and non-toxic. Product information 1. Insulation Material: Muscovite / Phlogopite mica plate 2. Heating Wire: Ni80Cr20, OCr25Al5A 3. Voltage Range/ Power Rating: depending upon application. 5. Operating Temperature: depending upon ratings, motor, construction of heater etc. 6. Dimension: customers` requirement. 7. Protection: customers` requirement.

2020 08/12

- Lithium micaLithium mica First, the composition and structure K (LiAl) 3 [AlSi 4 O 10] (OHF) 2, often containing Na and Rb, Cs and the like dilute alkali metal element. The lithium mica produced in the Fuxin granitic pegmatite in Liaoning contains Li 2 O4.51%, SiO 2 50.40%, Al 2 O 3 23.22%, K 2 O10.33%, Rb 2 O1.57%, Cs 2 O0 .08%, MnO2.17%, F7.51%. The mineral is a monoclinic system. Second, the materialized nature The crystal has a plate shape along (001) and has a pseudo-hexagonal outline, often a scaly or leaf-like aggregate. Lithium (001) is extremely complete, the sheet is elastic, the hardness is 2 to 3, the relative density is 2.8 to 2.9, rosy, light purple, white, sometimes colorless, glass luster, cleavage surface pearl luster. The mineral is soluble in H 3 PO 4 and is incompletely dissolved in HCl, HNO 3 , H 2 SO 4 . Due to the inclusion of Li, the blowpipe flame is red. Third, the identification features Lithium mica is easily recognized by its color, flaky crystal form and mineral symbiosis. Light-colored lithium mica is similar to muscovite and can be accurately identified by flame reaction. Fourth, the birthplace and origin Lithium mica mainly produces granitic pegmatite, which is symbiotic with quartz , feldspar , muscovite, spodumene, beryl and tourmaline . Mica is also produced in the lithium-rich Li, Rb, Cs, Nb, Ta granite, quartz, albite, topaz, wolframite, tantalum, niobium, iron ore and other symbiotic. Lithium mica fine particle aggregate-lithium mica rock, called lilac purple jade, is a new jade found in China in the 1970s. The granitic pegmatite containing lithium mica is produced in Xinjiang Altai and Henan Guanpo, and the Lithium-containing mica granite is produced in Yichun, Jiangxi.

2020 05/18

- High-voltage motor mica tape knowledgeThe mica tape is the main insulation of the high-voltage motor coil. Today, we introduces you to several new types of mica tape. Let's take a look. (1) High thermal conductivity mica tape and other high thermal conductivity insulating materials are important development directions in the future. Especially large-scale high-voltage motors and generators have urgent needs in this regard. Advantages of high thermal conductivity mica tape: reduce the thickness of insulation, reduce temperature rise, and improve the overall economic and technical indicators of the motor. Compared with ordinary mica tape, the thermal conductivity of high thermal conductivity mica tape is increased by 2 times, the temperature rise can be increased by about 10 ℃, and the corresponding motor capacity can be increased by 10-15%; it is an ideal material for motors. (2) Single-sided glass cloth reinforced silicone less adhesive tape is matched with silicone solvent-free impregnating paint. Good heat resistance, can reach 200 ~ 220 grade. Mainly used for high-power traction motors, nuclear power and other special motors. (3) The porous air-permeable mica tape is a kind of glass cloth and non-woven fabric reinforced less adhesive tape, which can use polyester imide adhesive or epoxy adhesive. It has good breathability and can be adapted to high-voltage and ultra-high-voltage motor insulation. Since the insulation thickness of high-voltage and ultra-high-voltage motors is more than 3.0mm, in order to improve the effect of VPI dipping paint, higher requirements are placed on the ventilation performance of mica tape. (4) The high mica content multi-tape is glass cloth reinforced multi-tape, which is suitable for molding or hydroforming process. Its outstanding feature is high mica content, mica content reaches nearly 60% (common multi-tape 5440-1 mica content is 40 %about). The high content of mica makes the mica tape and the insulating layer formed with higher electrical properties; it is mostly used for high-voltage motors and large-scale hydroelectric power generation. (5) Single-sided polyester film reinforced tape with adhesive as polyester imine system, has high dielectric strength and excellent process performance, can be used with unsaturated polyester imide impregnating paint, epoxy impregnating paint Through the VPI process to obtain excellent performance insulation, is conducive to thinning the insulation thickness.

2020 05/18

- Application of Synthetic Mica Tape in Class A Fire Resistant CableThe application field of Class A durable fire cable is gradually expanding, from the original offshore oil platform to aviation, aerospace, navigation, subway, tunnel, commercial building, hospital, dance hall, Metallurgical, chemical, and power plants require high fire resistance. In recent years, with the maturity of the A-grade refractory synthetic mica tape manufacturing technology, the A-grade fire-resistant cable made with it The amount of use is constantly increasing. As we all know, the refractory mica tape is divided into two grades: A grade (950-1000 ° C) and grade B (750-800 ° C). There are two kinds of phlogopite and synthetic mica tape, which are widely popular in the market. The former one It is generally suitable for the manufacture of Class B fire-resistant cables, which are suitable for both Class B fire-resistant cables and Class A fire-resistant cables. Class A belt can replace Class B belt to manufacture Class B fire resistant cable, while Class B belt does not. It can replace the Class A belt to manufacture Class A durable fire cables. Foreign mica tape manufacturers only produce Class B tapes, and there have been no reports of Class A synthetic tapes. Zui near, foreign countries have a film to strengthen Jinyun The master tape is trying to break into the Chinese market, trying to compete with the synthetic mica tape invented by the Chinese, but the film-type mica tape is also a B-band, and cannot be compared with the synthetic tape at all. And the price of performance is very different. This paper discusses the application of synthetic mica tape in Class A fire-resistant cable to clarify the slang of a foreign-made synthetic mica tape and the fire-resistant wire and cable manufactured by it. And expand the domestic and foreign markets of domestic grade A synthetic mica tape and fire resistant cable.

2020 05/18

- Mica processing technologyMica processing technology Industrial indicators Mica mining for the electrical industry must be a mica block with an effective area of more than 4 cm2 and no cracks or perforations. The non-mica minerals on the edges must not exceed 3 mm. After mica mining, the quality is divided into four categories according to the effective area, and the best special type area is larger than 65 square centimeters. Process flow The beneficiation of mica ore is the enrichment process of raw mica. Raw mica refers to mica crystal of any thickness in the original ore with a contour area greater than or equal to 4 cm2. The amount of raw mica in raw ore is called the raw mica mineralization rate, which is usually expressed by the weight of raw mica contained in the unit ore volume (kg/m3). The ratio of the total weight of raw mica in the concentrate obtained from the ore dressing to the total weight of the raw mica contained in the ore is called the recovery rate. The industry mainly uses mica natural crystals directly to process the desired products. The larger the mica crystal without defects, the higher its economic value. Therefore, in the process of beneficiation of mica ore, it is necessary to protect the natural crystals of mica from damage as much as possible. For the beneficiation of mica with a crystal contour area larger than 4 cm, it is mainly based on the difference in shape and friction coefficient between mica crystal and gangue. The commonly used methods are hand selection, friction selection and shape selection. For the crushed mica with a crystal contour area of less than 4 cm, it is mainly sorted according to the difference between its physical and chemical properties on the surface of the gangue. The method used is flotation. Mica seed dressing method and process a, hand selection Workers select the mica that has been separated by monomer on the mining face or the pit ore heap; the mica and the gangue are broken by hand hammer, and then the mica is selected. b, friction dressing The mica crystal and the gangue are separated according to the difference between the sliding friction coefficient of the slab-shaped mica crystal and the rolling friction coefficient of the spheroidal gangue. One of the devices used is a swash plate sorter. The machine is composed of a group of metals consisting of the swash plate, the swash plate of each length of 1350mm, width of 1000mm, under an angle larger than the inclination of the swash plate on a swash plate. A slit for collecting mica crystals is left at the lower end of each swash plate, and the width thereof is sequentially decreased in the order of slanting plates. The front edge of the slit is equipped with a triangular raft. During the sorting process, the large gangue rolls down to the stone pile; the mica and the smaller gangue block are blocked by the raft, and the sloping plate is dropped through the gap. The above process is repeated on the swash plate in turn to gradually separate the mica from the gangue. The friction beneficiation process and equipment are not perfect, so this method has not been widely used in mica ore dressing. c, shape dressing According to the shape of the mica crystal and the gangue, the ability to pass through the sieve slit and the sieve hole in the sieve is different, and the mica and the gangue are separated. When sorting, a sieve having two or more different sieve surface structures is used, generally the first sieve mesh is strip-shaped; the second sieve mesh is square. When the ore enters the sieve surface, due to vibration or rolling action, the flaky mica and small gangue can leak from the strip sieve to the second sieve; because the second layer is sieve, the gangue can be sieved. Lower flaky mica. The shape beneficiation method has the advantages of simple process, less equipment, high productivity, good sorting effect, etc., and thus has been widely used in mica mines. Mica broken process a, flotation Sorting according to the difference in surface physicochemical properties of mica and gangue. The ore is broken and ground to dissociate the mica monomer. Under the action of the agent, the mica becomes a foam product and is separated from the gangue. Mica flotation can be carried out in an acidic or alkaline slurry, and the long carbon chain amide cations and fatty acid anions are mica collectors . In the mica flotation process, three rough selections and three selections are required to obtain the mica concentrate. Therefore, mica ore float is used to recover mica and fine-grain mica below 14 mesh in pegmatite and mica schist. In China, mica ore flotation has not yet been produced and applied. b, wind selection Mica wind selection is mostly achieved through special equipment. The process is generally: crushing→sieving classification→wind selection. After the ore is crushed, the mica is basically formed into a flaky shape, and the gangue mineral feldspar , quartz and the like are in the form of massive particles. Accordingly, the multi-level grading is used to pre-divide the selected materials into narrower granules, and according to the difference in the levitation speed in the airflow, special air-conditioning equipment is used for sorting. The wind selection method is applicable to areas where water is scarce and has been used for actual production. Production example After the raw ore is manually sorted out of large mica, it is fed into the concentrating plant to fix the rod sieve, and the size of the sieve is 100mm. After the +100mm material is broken into the jaw crusher , it will enter the XB-602 vibrating screen sorting together with the product under the bar screen. The sieve has two layers of sieves, the upper layer is a bar sieve made of angle steel, the sieve width is 20 mm; the lower layer is a 20×20 mm square hole sieve, and after sorting, three kinds of products are obtained: materials larger than 20 mm sieve size, Mica and Liansheng body were selected from the hand, and the mica of more than 4cm2 was manually picked up by artificial crushing; the materials of less than 20mm sieve joint and larger than 20mm square mesh were also selected from the middle of the hand, and the artificial body was broken. After that, mica larger than 4cm2 is sorted; materials smaller than 20mm square mesh are all discarded as tailings. The beneficiation process consists of two parts: re-election and flotation. Re-election uses a spiral concentrator. The purpose is to remove coarse tailings. The selected coarse concentrate is re-elected into the flotation. Three mixing tanks are used before flotation. The first mixing tank is added with lignosulfonate (or sodium silicate) to disperse the slime, and then the sodium carbonate is added to adjust the pH of the slurry to about 10; the second blending tank is added with the fatty amine acetate cation collector to make It interacts with the side of the muscovite and adsorbs it; the fat in the third blending tank is added with the amine acetate salt cation collector, so that it absorbs with the muscovite layer, and then the foaming agent is added. After a rough selection three times, the mica concentrate is obtained. The mica concentrate has a grade of 98% and a recovery rate of 85%. Mica is mainly crystallized into a monoclinic system, and the crystals are pseudo-hexagonal flakes, scales, plates, and sometimes pseudo-hexagonal columns. Hardness 2~3, specific gravity 2.70~3.20. Mica powder has unique acid and alkali resistance chemical stability, heat resistance and non-combustibility, and good insulation. It is increasingly used in international and domestic markets. Can be used in the building materials industry instead of asbestos products. The industry mainly uses its insulation and heat resistance, as well as acid, alkali, pressure and strip resistance, as insulation materials for electrical equipment and electrical equipment; secondly, it is used to manufacture steam boilers and smelting furnaces. Windows and mechanical parts. Mica crushed and mica powder can be processed into mica paper, or it can replace various mica sheets to produce various low-cost, uniform thickness insulation materials.

2020 05/11

- Processing method and process of crushed micaProcessing method and process of crushed mica Processing method and process of crushed mica a. Flotation is sorted according to the difference in surface physicochemical properties of mica and gangue. The ore is broken and ground to dissociate the mica monomer. Under the action of the agent, the mica becomes a foam product and is separated from the gangue. Mica flotation can be carried out in an acidic or alkaline slurry, and the long carbon chain amide cations and fatty acid anions are mica collectors . In the mica flotation process, three rough selections and three selections are required to obtain the mica concentrate. Therefore, mica ore float is used to recover mica and fine-grain mica below 14 mesh in pegmatite and mica schist. In China, mica ore flotation has not yet been produced and applied. B. Wind-selected mica wind selection is realized by special equipment. The process is generally: crushing→sieving classification→wind selection. After the ore is crushed, the mica is basically formed into a flaky shape, and the gangue mineral feldspar , quartz and the like are in the form of massive particles. Accordingly, the multi-level grading is used to pre-divide the selected materials into narrower granules, and according to the difference in the levitation speed in the airflow, special air-conditioning equipment is used for sorting. The wind selection method is applicable to areas where water is scarce and has been used for actual production.

2020 05/11

- Mica miningMica mining The mining characteristics of mica deposits are: product industry requirements and prices demand for mining, mica is expensive, the larger the area, the more expensive it is. The mica crystals are protected from damage during mining, and the mining face cannot be used for mica equipment; mica The mining volume of ore is small, and it is in a remote mountainous area. The mining method is simple. The [mica broken" accumulated in the mica deposit has become the target of mining and utilization in recent years. The mica deposit mining method has open-pit mining method and underground mining method. Most of the deposits of industrial raw material mica with a reserve of less than 200t are open-pit mining. The division of the scale of mica deposits has not yet been regulated. Generally, the annual mining ore volume is between 60,000 and 100,000 tons, and the service life is 10 to 6 years. It is a large-scale mine, and its industrial raw material mica yield is 90-200t/a. The amount of mined ore in the mica deposit is a small mine compared to other minerals. Open-pit mining of mica deposits is commonly used for road development, slope improvement and trenchless development. Due to the small amount of mining, the road development has increased the use of 5t dump trucks, and the slopes have been upgraded and used to improve the trucks. Underground mining often uses inclined wells to develop or develop flats. Due to the small scale of mining and simple process, the open-pit mining uses the 01-30 hand-held rock drill for rock drilling, and also uses a down-the-hole drilling rig with a hole diameter of 80mm or 100mm. The blasthole arrangement should avoid the mica rich belt. After blasting, the mica ore is manually selected on the working surface and the excavator with 0.5m3 bucket capacity is loaded. 5t dump truck for working face transportation. Underground mining compared to other non-metallic minerals has its own peculiarities. Since the mica ore and surrounding rock are hard and stable, all the mining methods such as the retention method, the filling method and the comprehensive method are adopted. Due to the high value of mica, the mica crystals are manually selected on the working surface and concentrated. In order to protect the mica crystals, sorting measures should be taken when dropping the mine. For the giant crystal mica belt which is integrated and stabilized near the top plate, the hole is 0.3~0.6m away from the ore body during rock drilling, and then the bottom of the giant crystal mica belt is pulled down. The blasthole contains a small amount of explosives, so that the mica belt after blasting is presented. Loose state, with the tip of the tip, for the discontinuous disseminated ore body according to the mica distribution law of the working surface, do not damage the mica crystal as the principle, choose the location of the blasthole, such as drilling to a certain depth after encountering mica Crystals can't continue to be eye-catching, and consider whether the blasthole is loaded. The operation of ore in the working face cannot be carried out with antimony ore equipment. The mining process of the mica deposit is to drill, blast, manually move to the mining patio, artificially fill, and the mine leaks to the mine car located in the transportation lane.

2020 05/11

- Improvement of properties of mica titanium pearlescent pigment by surface modificationTitanium-mica pearlescent pigment is a new type of non metallic decorative paint. It is made of mica powder and coated with a high refractive index metal oxide transparent film. Through the interference or reflection of light, the pearly luster from soft satin to dazzling flicker is produced. Developed by DuPont in 1963, this new pearlescent pigment has been rapidly developed due to its weather resistance, non-toxicity, acid resistance, alkali resistance, non-conductivity, non-magnetic properties, and chemical stability. It is widely used in the automotive industry. Coatings, plastics, leather, ink printing, ceramics and cosmetics, toys, rubber, decorative and other fields. At present, with the expansion of the application range of mica pearlescent pigments, its performance is higher, and its hiding power, coloring, transparency, stability and light resistance are unsatisfactory, and it is limited in application. Therefore, improving its performance is currently the main direction of pearl pigment research. Surface modification of inorganic materials is a new high-tech in the field of materials science in recent years. It changes its surface properties by physical, chemical and mechanical methods. People use these modification principles to conduct in-depth research on the development of high-grade mica pearlescent pigments. 2 method for improving the performance of mica titanium pearlescent pigment 2.1 Multi-cladding structure for improving hiding performance The mica pearlescent pigment developed in the early stage is mainly composed of a single-clad structure, and the technology is relatively mature. Due to the poor covering performance of the single-cladding structure, there are certain restrictions on the application in some specific occasions. Many cladding structures have been developed. The multi-clad structure has a multi-layer colorless transparent film, which combines the natural metal oxide film and the nano-scale metal particles to form a pearlescent effect on the light, and a strong scattering effect on the light. A metallic luster is obtained, which improves the hiding power. The synthesis process is as follows: Mica→mica suspension→coated titanium dioxide→low temperature anoxic calcination→coated Cr(OH) 3 The low temperature oxygen-free calcination is carried out in an argon atmosphere below 200 ° C, and the surface of the TiO 2 film on the surface of the mica is reduced to a low-valent titanium oxide and a metal titanium. The TiO 2 film is further coated with a Cr(OH) 3 film, and a layer of low-valent titanium oxide and titanium metal distributed in a spot shape are deposited between the TiO 2 and Cr(OH) 3 films. The three-coated mica pearlescent pigment has high hiding power and coloring ability, but the pearlescent effect is reduced compared with the double-coated mica pearlescent pigment. To solve this problem, the current method is to increase the transparency of the metal oxide film or to cover two thick layers of a colorless transparent metal oxide film. There are also reports on four-clad and multi-coated pearlescent pigments. 2.2 Improving the stability of pearlescent pigments Pearlescent pigments are easily damaged by the dual effects of ultraviolet radiation and moisture. The US patent reported that the improved pearlescent pigments have good gloss stability and pure color. The pigment is prepared as follows: Based on metal oxide TiO 2 coated mica flakes, disperse it in water to prepare a slurry, and then slowly add one or more solutions containing dissolved metal salts or mixtures (such as chromium methacrylate and Na 2 HPO 4 • 2H 2 0), adjust the pH to 4-7, precipitate the metal salt on the surface of the pigment under the action of precipitant (FeS0 4 •7H 2 0), wash by filtration, dry at 130 ° C, and the obtained pigment is pure. No agglomerates, dense coating, and its stability is significantly better than the original pearlescent pigment. [next] 2.3 Improving transparency and tinting strength For coated mica pearlescent pigments, the quality of the metal oxide deposited on the mica plate, especially the crystal size of the precipitate, plays a key role in the degree of light scattering. If the crystal is too small, the pearl luster and the interference color will disappear, and the transparency and tinting strength of the pearl pigment will decrease. According to optical theory, when the particle size falls to half the wavelength of visible light, the light penetrates the particle without being refracted. Such particles will be transparent. The Al 2 0 3 particles are much smaller than this value, so the coating is substantially transparent. The methods for improving transparency and coloring properties reported in the U.S. patent are as follows: The method is prepared by coprecipitating TiO 2 with AL 2 O 3 and SiO 2 on mica flakes. The mica flakes (particle size 10-70 μm, thickness 0.1-5 μm) are suspended in water to prepare a slurry, and the pH is adjusted to 1.5-2.5 with a suitable acid (such as hydrochloric acid), and then heated to 70 ° C - 80 ° C while measuring Add TiCL4 solution, ALCL 3 •6H 2 0 solution (containing hydrochloric acid) and alkaline Na 2 SiO 3 solution (containing NaOH). The speed and quantity of addition should be kept constant at pH 0.2, and the corresponding hydroxide or The hydrated oxide is completely precipitated on the surface of the mica plate. After the required blue interference color thickness is reached, the coating is stopped, washed by filtration, dried at 120 ° C, calcined at 700 ° C - 1000 ° C for 30 min, and the metal hydroxide or hydrated oxide is transformed. As a corresponding oxide, the mica has excellent transparency and pearlescent properties. 2.4 Improving the Lightfastness of Pearlescent Pigments When pearlescent pigments are placed for a long time or applied to paint films and coatings, the pearlescent effect will be weakened, discolored, powdered, and peeled off. The reason is that the surface coated Ti0 2 has strong photochemical activity. When it absorbs light of less than 405 nm wavelength, it will change from electron valence band to valence band, thereby forming electron holes and causing chemical changes in the surrounding medium. . In order to prevent this phenomenon, a uniform protective film may be coated on the surface of the mica titanium to seal the photoactive dots of the original TiO 2 to improve the light resistance. A method for improving the light resistance of pearlescent pigments is as follows: 4 g of silver- white mica titanium pearlescent pigment is placed in a 250 ml four-necked flask, 100 ml of deionized water is added, and the pH is adjusted to 7-8 with 2 mol/L NaOH, and then Place in a constant temperature water bath, stir to warm to 80 ° C, and then add a mass fraction of 0.5% ALCL 3 solution, in order to maintain the pH value of the solution, while adding 2mol / L NaOH solution, the end of the feed, continue to heat stirring for 1h, filtration, The filter cake was dried to 110 ° C until it was washed, and calcined at 500 ° C for 1 h in a muffle furnace to obtain a mica pearlescent pigment having greatly improved light resistance. 2.5 Using a crystal form conversion agent to increase the refractive index of pearlescent pigments When preparing a mica titanium pearlescent pigment, the titanium salt hydrolyzes the TiO 2 deposited on the mica plate, and in the high temperature calcination, an anatase type and a rutile type crystal structure can be formed, The refractive index is higher than the former, so the rutile-type mica titanium pigment has a good pearlescent effect. However, in the crystallization process of mica titanium, it is difficult to ensure that the titanium dioxide is completely converted to the rutile type by controlling the temperature and time, so the rutile accelerator can be added during the preparation process. At present, a mixture of divalent tin salt and hydrogen peroxide is mainly used, and the optimum amount of tin salt is preferably 20% of the amount of titanium salt. 2.6 Enhancing the coloring ability of mica pearlescent pigments with organic colorants Organic pigments have a vivid color and can be coated on the surface of mica by chemical adsorption. At present, the main method of coating organic pigments is chemical adsorption, and there are two different methods depending on the treatment agent: (1) Inorganic color precipitation coating method The preparation process of the European patent report is as follows: Mica pearlescent pigment→organic pigment or dye→slaker coating→filtering→drying→product Adding a coloring agent to the organic pigment or dye to fix the adsorption. The lake former used is generally a compound such as AL, Zr, Ca, Ba, Sr or the like. This process has the advantage of being able to be carried out at higher mass fractions and lower temperatures. [next] (2) Organic coupling agent coating method The coupling agent has an amphoteric structure, and a part of the molecules in the molecule or react with various functional groups on the surface of the inorganic material to form a strong chemical bond, and another part of the group may react with the organic substance. A chemical or physical reaction that produces a "molecular bridge" with special functions between inorganic materials and organic pigment molecules. For example, using an organic chromate coupling agent, the coupling agent can be first reacted with mica, and then reacted with an organic pigment, or the mica pearlescent pigment can be directly mixed with a coupling agent or an organic pigment to react. Generally, the amount of coupling agent is 0.01%-2.0% of the mica mass fraction. 3 Mica pearl pigment research direction prediction The development history of mica titanium pearlescent pigment is short, but because of its unique decorative effect and non-toxic, acid-resistant, alkali-resistant, non-conductive, non-magnetic, chemically stable and other excellent characteristics, application The prospects are very broad. (1) With the continuous improvement of the appearance quality requirements of articles, the application field of mica titanium pearlescent pigments is expanding day by day, so higher requirements are placed on its performance. At present, little work has been done on the surface modification of pearlescent pigments. its influence future performance will focus mainly used surface treating agent such as silicon oxide, aluminum oxide pigments for more in-depth study; (2) Multi-coating coloring mica pearlescent pigments have better performance than single-coating pigments due to their structural improvement, and can meet the needs of some special occasions, which will be the focus of another research in the future; (3) Due to the high pearlescent color of rutile type, the development of Jinhong Petrochemical Accelerator is of great significance for the preparation of high quality pearl mica.

2020 05/07

- Development and utilization status of micaThere are more than 30 mining areas in China. The main producing areas are: Xinjiang Altai Muscovite Mine, Sichuan Danba Muscovite Mine, Inner Mongolia Tuguiula Muscovite Mine, Shaanxi Danfeng Muscovite Mine, Jilin Ji'an Phlogopite Mine, Henan Zhenping gold mica mine and Hebei Quyang Baiyun parent mine. Most of them produce crushed mica and its products while producing industrial raw materials. Some metallurgical companies also recover broken mica from the beneficiation tailings and supply the market. Xinjiang non-metallic minerals company, Sichuan Danba Mica Mine, Ya'an Mica Factory and Inner Mongolia Tugui Wula Mica Mine, etc., produce mica powder and mica products. The production of mica paper is Sichuan Ya'an Mica Company, which is used by more than 350 enterprises in 27 provinces and cities nationwide, and the products are tested abroad. Xinjiang Mica No. 1 Factory produces high temperature resistant mica board. The manufacturers of mica powder are Ya'an Mica Factory and Hebei Lingshou. The products can be exported in addition to domestic demand. Problem 1. Low comprehensive utilization rate: the comprehensive utilization of muscovite, foreign countries have achieved no waste in the factory, and 100% of raw materials are used. The comprehensive utilization rate of China's muscovite is about 40%, and it still needs to expand its application fields. 2. The application field is narrow: In recent years, the comprehensive utilization of muscovite has been expanding, and it has achieved good applications in the fields of building materials, earthquake resistance, lubrication, organic and inorganic composite materials, and sealing materials. There are 10 categories and more than 100 varieties of products processed comprehensively. China's application field is relatively narrow, solutions Strengthen technical research, improve comprehensive utilization rate and continuously expand application areas, and broaden the market. development trend From the general trend, due to the success of artificial synthesis of large crystals of muscovite, the demand for large muscovite in the world will gradually decrease, so the exploitation of natural large muscovite will decrease year by year. However, the demand for debris muscovite will continue to increase. The existing high-quality muscovite in the world is far from meeting the needs, and the development of synthetic muscovite is accelerating. The current consumption structure of muscovite has changed. It is estimated that the demand for mica in the world will continue to decline at a rate of 4.6% per year, while the demand for broken mica will continue to grow at an average rate of 1.5% per year. Muscovite comprehensive utilization products----mica paper and wet-milled mica powder and mica deep-processing products are all relatively popular products on the international market. The demand for the tube feeding mica is balanced, and the capacitor chip and the outer thick mica are basically saturated. Natural flaky mica is generally replaced by alternative materials. However, as a comprehensive utilization product of muscovite, mica paper and mica powder as well as deep-processed products such as mica insulation products and mica paper appliances have begun to sell well. (1) The mica paper market machinery department has long determined that mica paper insulation materials for motors mainly use mica paper instead of mica flakes. In 1987, China's new power generation equipment capacity was 9.2 million kilowatts. It is usually calculated by adding 5 tons of mica paper to the newly added capacity of 100,000 kilowatts. It requires about 460 tons of mica paper. China's energy industry is the focus of development in the future. During the "Seventh Five-Year Plan" period, it is planned to reach a generating capacity of 10 million kilowatts per year. The annual requirement for mica paper is not less than 500 tons, and a total of more than 2,500 tons is required. In addition, China's power generation capacity has reached 100 million kilowatts in 1987. If 20-30% replacement maintenance is considered, the mica paper required for maintenance is also considerable. In addition, there are a large number of industrial and household appliances that also require a large number of products such as insulating cardboard. The domestic mica paper market is promising. (2) Mica powder market China's electric welding rod production requires about 15,000 tons of mica powder per year, 140,000 tons of mica powder for linoleum paper, 2,000 tons of mica powder for fire-fighting equipment, plus the newly developed mica powder application field, from development In the trend, the demand for mica powder may increase further.

2020 05/07

- Classification and introduction of Mica titanium pearlescent pigmentsMica titanium pearlescent pigments can be roughly classified into three types: silver-white, rainbow, and colored. Silver-white pearlescent pigments, because white light reflects on the titanium surface of mica and does not transmit light, can only present a single silver-white phase, but due to the difference in the particle size of mica and the coating rate of TiO2, it will appear as a visual angle Pearl-like mercerized changes. It is the most versatile pearlescent pigment, but it has poor hiding power. The rainbow type is coated with a layer of TiO2 or other metal oxides with higher refractive index, such as Fe2O3, Cr2O3, SnO2, etc., on the flaky mica substrate, and it is excellently produced through multi-level reflection and interference of light. Pearl effect and flop effect. Since this type of pigment both reflects light and transmits light, light at certain wavelengths is strengthened, while others are weakened to exhibit different hue. The biggest advantage of rainbow-type pearlescent pigments is that they can be matched like ordinary pigments, and the resulting complex color is bright and beautiful. The coloring type is based on two kinds of pearlescent pigments of silver white type and rainbow type, and then add a coloring pigment or a dye capsule. This kind of pigment can absorb some light in the visible spectrum. If the reflection color of the absorbing color and the oxide coated mica pigment have the same hue, then the absorption color increases, and the color can be seen at all angles; if the hue is different, it can only be The reflection color is seen at the mirror angle, and the color of the absorption pigment is seen at other angles. Between these two extremes, the transition color can be seen. The pigmented pearlescent pigments are optical pigments that utilize the pearlescent and colored materials of mica titanium to absorb some of the visible light and become a class of pigments with a full spectrum of color and a bright color.

2020 05/07

- Standard for mica stone beneficiationshape: According to the shape of the muscovite crystal and the gangue, the ability to pass through the sieve slit and the sieve hole in the sieve is different, so that the muscovite and the gangue are separated. When sorting, a sieve having two or more different sieve surface structures is used, generally the first sieve mesh is strip-shaped; the second sieve mesh is square. When the ore enters the sieve surface, due to vibration or rolling action, the flaky muscovite and small gangue can leak from the strip screen to the second screen; because the second layer is sieve, the gangue can be screened. Leave a sheet of muscovite. The shape beneficiation method has the advantages of simple process, less equipment, high productivity, good sorting effect, etc., and thus has been widely used in muscovite mines. Method flow: 1. flotation Sorting according to the difference in surface physicochemical properties of muscovite and gangue. After the ore is crushed and ground, the muscovite monomer is dissociated. Under the action of the agent, the muscovite becomes a foam product and is separated from the gangue. The muscovite flotation can be carried out in an acidic or alkaline slurry, and the long carbon chain amide cation and the fatty acid anion are muscovite collectors. In the muscovite flotation process, three sections of rough selection and three sections are selected to obtain the muscovite concentrate. Therefore, muscovite ore float is used to recover muscovite and fine-grained mica below 14 mesh in pegmatite and muscovite schist. In China, muscovite ore flotation has not yet been produced and applied. 2. wind selection Muscovite wind selection is achieved through special equipment. The process is generally: crushing→sieving classification→wind selection. After the ore is crushed, the muscovite basically forms a flaky shape, and the gangue mineral feldspar, quartz and the like are in the form of massive particles. Accordingly, the multi-level grading is used to pre-divide the selected materials into narrower granules, and according to the difference in the levitation speed in the airflow, special air-conditioning equipment is used for sorting. The wind selection method is applicable to areas where water is scarce and has been used for actual production.

2020 04/27

- Mica use and technical and indicatorsSheet mica is generally used for electronic tube sheets and capacitor sheets for the radio industry, mica sheets for motor manufacturing, various specifications for use in household appliances, telephones, and lighting. Broken mica can produce a variety of mica paper, used as insulation material, widely used in the electrical industry; production of various mica powder, mostly used in linoleum roofing materials, also used in cable wrap and electrode production; also used in the production of mica ceramics Mica fused cast products, mica reinforced plastics, pearlescent pigments and new mica building materials. The primary raw material used in industry is called industrial raw material mica, which refers to the raw ore mined by the mine. The mica block with both sides flattened and the effective area is greater than or equal to 4cm 2 obtained through preliminary mineral processing . Industrial raw material mica appearance quality conditions: cracks, perforations, bonds, wrinkles, inlays, continuous biological and feathery stalk layers are not allowed in the effective area, and weathered mica with complete loss of elasticity and flexibility is not allowed; mica crystals Mica fragments that are easy to fall off are not allowed, and non-mica minerals and full-chip biotite coatings are not allowed on the surface of the crystal; non-mica minerals on the edges of mica crystals, not more than 3 mm in the radial direction, non-mica minerals with concave angles The depth shall not exceed 7mm; the maximum thickness of the thickest side of the wedge-shaped mica shall not exceed 10mm; the thickness of the plate-like mica crystal is not limited. The industrial raw material mica is divided into the following inscribed rectangles of the largest effective area of either side according to the mica crystal: special, I, II, III, IV5, and divided into two grades according to the proportion of the effective area of the spots. Mica sheet processed with industrial raw material mica into a thickness of 0.1 to 2 mm and an effective area of 4 cm 2 or more is called thick mica. According to the appearance quality and use, it is divided into special grades A, B, C and 4, according to the maximum within the film. The area of the inscribed rectangle is divided into 9 models. The thick mica is further stripped and processed into thin mica. A representative sample shall be selected for electrical performance testing and the breakdown voltage shall not be lower than the relevant requirements. The broken mica is the general term for the fine mica produced and the waste residue after processing and stripping. According to the professional standard ZBQ-6303-87 of the People's Republic of China, according to the requirements of use, the broken mica is divided into three categories: I, II and III. Class I is used to make non-calcined powder mica paper; Class II is used for making calcined powder mica paper, and Class III is used for grinding mica powder. The quality indicators should meet the requirements of the following table. Other requirements for various fine products of fine mica raw materials are summarized as follows: The technical requirements of mica paper for pulping mica scales: the thickness of the scale should be micron or thinner, the thickness of each piece should be uniform, the diameter of the scale should be larger than the thickness, generally should be greater than 50, better than 100, but should meet different The requirements for soaking, mica scales are uniform in size, with few surface defects, clean and pure. Requirements of mica powder for natural mica ceramics (mica glass): mica powder is white, moisture is less than 1.5%, magnetic content is less than 0.02%, pH is 7.0-8.0, sand content is less than 0.1%, and HCl soluble content is less than 4. %. Synthetic mica ceramics (mica plastic) requirements for mica powder: mica powder greater than 98%, glass phase less than 0.8%, carbide less than 0.02%, olivine, mullite less than 0.5%, Fe, Ca impurities less than 0.2%, other Less than 0.2%. Mica ceramics have certain requirements on the particle size of mica powder due to the different molding processes. Generally, the mica powder used in hot press forming is mainly -60+120 mesh. The mica powder used for die casting is mainly -80+120 mesh. Sericite is a subspecies of densely packed microcrystalline aggregates of muscovite. It can be stripped into pole pieces with a thickness of 1 μm or less and used as a filler and oil drilling mud. There is currently no uniform requirement for its quality. Generally, the fineness is 0.2 to 1 μm for papermaking filler, 20 to 200 mesh for plastic filler, and 160 to 250 mesh for rubber filler. For ceramic batching, high whiteness and good plasticity are required; in coating, it is required to have Fine fineness, heat resistance is not less than 500 °C.

2020 04/27

- Mica tube insulation classificationThere are many types of mica pipes. Different categories have different uses. I will briefly introduce the categories and uses of several types of mica pipes for everyone: 1. The 5931-2 shellac mica tube is glued into a tube blank using mica flakes and shellac. 2. The 5932-2 epoxy mica tube is made of mica sheet and epoxy resin glued into tube blanks. 3, 5933-2 shellac mica pipe is glued with mica and shellac paint E-glass cloth The above are all made by hot rolling. The mica tube is suitable for the insulation of the motor outlet sleeve. The surface of the mica tube should be smooth and free of delamination, and must not contain impurities or gaps. The inner wall is allowed to have slight creases, and both ends should be cut cleanly, but the end slope must not exceed half of the length tolerance. Ningbo Ram Electric Material Ltd. is a company specializing in the mica and related heat insulation material for more than 10 years, and is the biggest mica mineral importer and mica product exporter in China. Our main products cover: Mica products (mica plate; mica tape), fiberglass sleeving, Kapton film, Ceramic parts, heating wire, Heating elements, Rubber parts, plastic products, Metal parts, and so on. Certificated as an A-grade entity by Customs of Chinese Government, NBRAM is a great team, skillful, and experienced Our spirit: FUN, FAIRNESS, INTEGRITY, RESPONSIBILITY Choose NBRAM, choose your best partner to your success.

2020 04/27

- Mica tube application range and physical stateMica tubes are high-performance silicone adhesives and high-performance silicone rubber made of hard tube insulating materials. With good electrical insulation properties and high mechanical strength, it is suitable for the insulation of electrode rods or outlet tubes of various electrical appliances, motors, smelting furnaces and other equipment. Compared with the traditional ceramic tube, the advantage of mica tube is easy to control wall thickness and ellipticity, even discharge, not easy to break, etc. It is an ideal alternative part of ceramic tube. First of all, mica tube products: 1. Thermosetting tube Heat-resisting mica tube is impregnated with mica paper after the silicone rubber is baked by these insulating products. 2, the scope of application of mica tube: The mica tube can be used as an electrothermal device at a temperature of 900 degrees. 3, the physical state of the mica tube: Appearance: smooth surface, no layers, foam and wrinkles, trim marks but no more than the wall thickness tolerance index provides a slight wrinkle defect on the inner wall, cut neatly ends.

2020 04/21

- Application of mica tape in insulation engineeringMica tape is a kind of high-efficiency fireproof insulation tape, which has the advantages of low price and high insulation performance For example, the fire-resistant mica tape dedicated to cable engineering is a high-performance mica insulation product with excellent high-temperature resistance and combustion resistance. The powder mica tape has good softness in normal condition and is suitable for the main fire-resistant insulation layer in various fire-resistant cables. In the event of fire burning, there is basically no volatilization of harmful smoke, so this product is not only effective for cables, but also very safe. Synthetic refractory mica tape is an enhanced version of general fire resistant mica tape, with high temperature resistance and absolute flame retardant effect. Its production process is to synthesize mica to replace hydroxyl with fluoride ion, and to synthesize artificial mica with large size and complete crystal form under normal pressure conditions. Synthetic mica tape is made of mica paper made from synthetic mica, and is made by bonding glass cloth to one side or both sides with an adhesive. The glass cloth is affixed to one side of the mica paper called "single sided tape," and both sides are called "double sided tapes." In the manufacturing process, several layers of structure are glued together, then dried in a furnace, then wound up, and then cut into different sizes of tape.

2020 04/21

- Overview of basic types of heating elementsHeating elements have a wide range of applications in industry and home. When the current passes through the conductor, it heats the conductor and generates heat. The heat generated by this current is called electric heat. We can use electrothermal theory to make a variety of electric heaters, such as electric iron, electric oven, water heater, electric incubator, electric stove, electric iron and so on. In the China Manufacturing Network product catalog, electric heating equipment is divided into the following sub-categories: Electric heater electric heating coil, electric heating plate electric heating tube, heating electric heating wire, electric heating wire other electric heating equipment thermal resistance thermocouple The above classification is mainly based on the classification of electric heating products. If it is subdivided by its shape, the market now has flanged tubes, shaped heaters, flammable and explosive heating tubes, heavy oil heaters, straight heating tubes, U-shaped heating tubes, W-shaped heating tubes, spiral heating Appliances and other products are widely used. According to the different conductors and temperatures, Baidu Encyclopedia is divided into the following types: According to conductors: Metal heating wire type heating element (0-700 degrees) PTC type heating element (self-limit temperature, self-control temperature) Electrothermal film type heating element (metal type and spray type) According to the temperature difference is divided into: Low-temperature type (up to 100 degrees, commonly used for liquid heating, such as water) Medium temperature type (100-500 degrees, commonly used in electric furnace, baking equipment) High-temperature type (500 degrees to -1100 degrees is commonly used in high-temperature furnaces, ultra-high temperature type (1100-1300 degrees, often used in test equipment, heating furnaces for special occasions) Although domestic manufacturers still face various technical difficulties, we should recognize our achievements in recent years. In the boom of hyperthermia heating elements, many small and medium-sized enterprises have also emerged, constantly improving the quality of their own products, and moving further and further away on the road to technological solutions.

2020 04/21

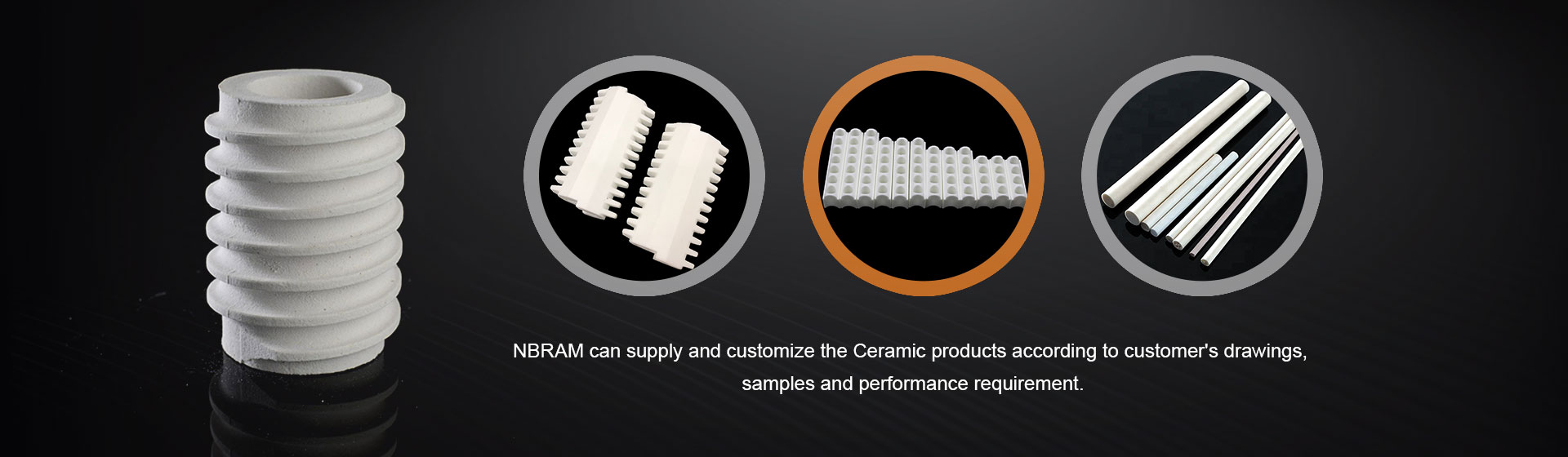

- Chinese mica supplier with 50 years of experienceWe do mica and related heat insulation material for more than 10 years, and is the biggest mica mineral importer and mica product exporter in China. Located in Ningbo, seaport city in eastern China, easily accessed by sea, air and land which adjoins Shanghai by cross the longest bridge in the world over the hang Zhou bay. Our main products cover Mica products (mica plate; mica tape), fiberglass sleeving, Kapton film, Ceramic parts, heating wire, Heating elements, Rubber parts, plastic products, Metal parts, and so on. Certificated as an A-grade entity by Customs of Chinese Government, NBRAM is a great team, skillful, and experienced Our spirit: FUN, FAIRNESS, INTEGRITY, RESPONSIBILITY Choose NBRAM, choose your best partner to your success.

2019 04/17

Email to this supplier